How We Make Our Stuff

Everything starts with a painting or study of a critter. For a ceramic piece, the painting is done from scratch right on the piece of bisque using underglazes. Then it has to be fired, glazed and refired to achieve it's final finish. No two pieces are exactly alike, even when we are asked to paint two of the same scene!

For our other items, M. K. paints the study on Arches paper with Lukas gouaches. The artwork is scanned and digitally remastered to fit whatever item we're going to make. It's a pretty straight forward process for note cards. Our laser printers print the desired quantity of a design onto Cougar papers. The cards are then folded and packed into their little clear boxes by hand.

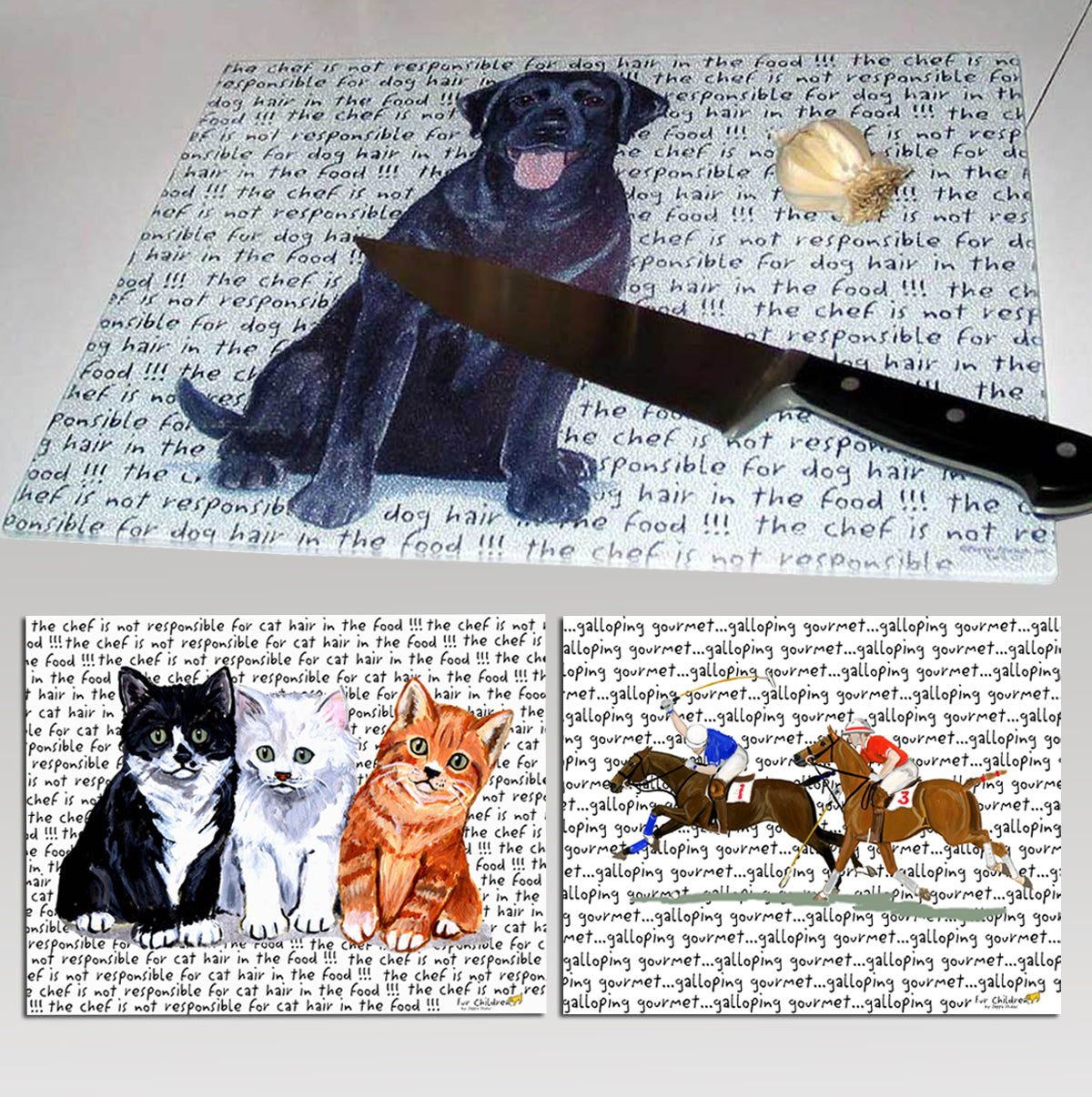

Everything else, except Waterdog glassware, is made using a process called dye sublimation. The digitally remastered artwork is sized to the item to decorate. It is then printed with a special printer and special inks onto special paper. A combination of heat and pressure transfers the image onto the item which has been specially coated to receive it. Flat items receive the transfer in a heat press (like a giant iron...finished coasters are shown on the press above). Dimensional items, like mugs, have the image strapped to them with rubber wraps by hand and are heated in our kilns.

Waterdog crystal is decorated with water-slide "faux etch" decals. The glasses themselves are made in the USA except for our stemmed wine glasses. They are German. After the decals are applied by hand, the glassware is fired in our kilns to permanently fuse the design to the glass.